As we close in on the end of a decade, technology will continue to evolve at an extraordinary pace. We’re likely to see massive advancements in space travel, increased technological integrations in our everyday lives and significant steps taken in quantum computing in the 2020’s.

For the here and now though, it seems as though everything is changing for the better on a day-by-day basis; which means it’s never easy to predict what might make the next big wave. In this blog, we’ve put together our top picks technological picks that could impact manufacturing in 2020.

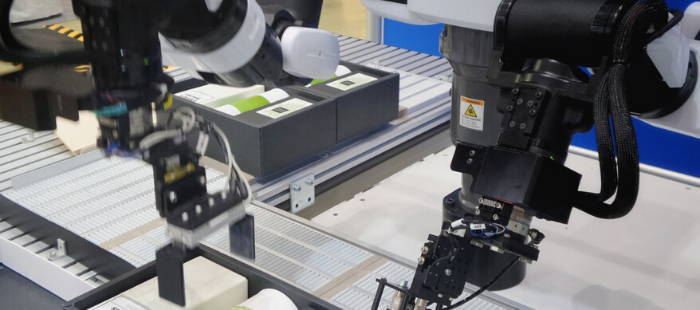

#1: Automation

Automation is a word that is often unclear, and not something that can be easily defined. It ultimately refers to technology such as cloud computing, robotics and big data. For many manufacturing companies out there at the moment, automation will become a critical driving force in the years to come, if it isn’t already.

The future of automation means that there are endless possibilities for our industry. Those in the know, believe that utilising all of the highly advanced technologies that come along with automation will bring down costs and make lives easier.

Whether automation works out for the better, remains to be seen, but what we are sure about is that it will continue to be implemented at great pace.

#2: 5G

5G is expected to expand rapidly in 2020, as more technology companies develop more 5G capable devices, and telecoms companies continue to meet their deployment goals.

5G will bring higher broadband speeds and more resilient wireless and mobile networks, which will allow a greater level of automation and technological advancements, which will make everything more reliable and above all, much faster.

#3: Artificial Intelligence

While AI could technically be considered as automation, the speed of its advancement is enough to consider it a separate point.

AI has been on technology trend lists for years now, but 2020 is likely to continue to push advancements in the coming decade and beyond.

Computers are now more than capable of learning about the environment around them in the same way that humans can. Even your mobile phone can store data about its surroundings to offer a more exceptional experience for their owners.

However, with the increasing computer speeds and power, AI will be able to perform increasingly complex tasks, which humans alone are unable to do in the manufacturing industry.

Modern AI is currently utilising facial recognition and voice technology. In the coming decade, we may find that AI will no longer need human interaction to grow smarter and learn more about its surroundings.

#4: Blockchain

Blockchain technology is most commonly associated with cryptocurrency, but it has been implemented in a few industries to great effect. 2020 may see Blockchain infrastructure used more readily in manufacturing to revolutionise supply chains and improve data and inventory management.

Blockchain allows secure technological communication, which prevents malicious attacks during data transfer. The basis of the technology has been around since the 1980s and has been gaining serious traction in various technology-heavy sectors in recent years and looks set to increase its utilisation in the manufacturing industry in 2020.

#5: Analytical Data

Analytical data is playing an increasingly pivotal role in growth and development strategies for companies all over the world. Not only does it help you to understand how you’re performing in your niche, but it can also help you understand when the market may shift again.

Segmenting analytical data may seem simple, but it actually takes a great of processing to turn vast portions of data into something measurable and useful.

Advancements in cloud computing, IoT, and big data, will gain more traction as machine learning and faster connection speeds continue to rise. This will help a manufacturing business gather data more quickly, as well as being able to identify issues, implement solutions and monitor activities across the board.

If you have any questions about anything we’ve covered in this blog, or you’d like to discuss any of our services, then why not contact us today?