Overview

A UK-based food ingredients manufacturer, part of a global group with multiple international production sites, specialises in the production of high-quality sweet ingredients for use in cereals, snack bars and bakery products.

In Spring 2024, Control Freaks Ltd was appointed to deliver a complete controls refurbishment on an ageing moulder and oven production line. The equipment had been operating reliably for many years, however a modernisation programme was required to support ongoing safety, improve reliability, enhance diagnostics and prepare the line for future operational demands.

Situation

The production line had been in service for an extended period, with various incremental updates applied over its lifetime. To ensure ongoing safety, maintain alignment with current standards and support long-term operational resilience, the manufacturer sought a modernised control and safety solution.

In addition, operators required clearer visibility of the system and safety states, faster batch change capability and improved diagnostic support. Ageing control hardware was also beginning to impact day-to-day reliability and maintainability.

“The original system had served us well, but reliability was becoming an issue. We needed a modern, safe and flexible solution that would support our operators and maintain production consistency.” – The client, Engineering Manager.

The objective was clear: maintain long-term system integrity, improve uptime and deliver a safety-led, energy-efficient control platform capable of supporting the site for years to come.

Objectives

The project was required to deliver:

• Higher reliability and reduced unplanned downtime

• Integrated, modern safety with operator-friendly visibility

• Faster, more flexible batch changes

• Enhanced fault diagnostics and remote support capability

• Reduced energy consumption • Better oven temperature stability and product quality

• Better oven temperature stability and product quality

The Solution

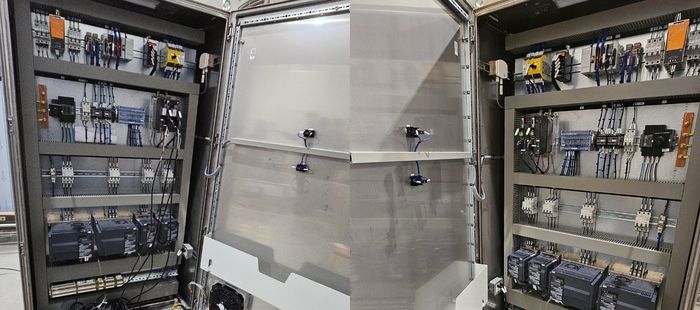

1. Complete Controls and Pneumatics RefurbishmentOur expert team at Control Freaks designed and installed a modernised control panel with replacement pneumatics to deliver consistent tracking, movement and operator control. Installation occurred over planned weekend shutdowns to protect ongoing production.

2. Mitsubishi Automation Platform

As a Mitsubishi Electric Approved Solutions Partner, we selected proven components known for reliability in high-temperature bakery environments:

• FX5U PLC, using built-in PID for accurate oven temperature control

• FR-E800 Inverters, providing energy-efficient control of extraction fans

• GT2510 HMI, matching site standards and improving operator usability

“The Mitsubishi platform allowed us to develop the software rapidly and with confidence. We know how these products behave in hot bakery environments, and their performance and robustness are consistently strong.”

– Ian Davison, Control Freaks Commercial Manager.

3. Integrated Functional Safety with Wieland Samos PRO SP-COP

A key element of the upgrade was the introduction of a modern, configurable safety control system to support ongoing safety and future flexibility. The solution provides clear diagnostic feedback and protected safety logic, ensuring safety functions cannot be bypassed while remaining adaptable to future production changes.

Integrated benefits included:

• Clear indication of which safety device or gate is active

• Faster fault resolution through immediate switch-failure diagnostics

• Increased safety integrity through undefeatable logic and protected programming

• Flexibility for future process changes

“Modern safety is not just about stopping equipment. It is about providing clear information, supporting maintenance teams and ensuring safety functions remain protected and dependable over time.”- Clint Johnson, Control Freaks Founder.

Impact

Improved Line Uptime – Enhanced diagnostics and a reliable new control architecture have delivered a significant improvement in uptime, supporting on-site and remote troubleshooting.

Increased Operator Safety and Confidence – Operators now have immediate clarity on which safety device has been activated, reducing restart times and supporting safe working practices.

“The new safety system has made an immediate difference. Our operators can see exactly what is happening, and we spend far less time fault-finding after a stop event.”

– The Client, Maintenance Manager.

Energy Savings – The introduction of FR-E800 inverter control for extraction fans has resulted in a 12% reduction in energy consumption, supported by replacing mechanical dampers with demand-based speed control.

Consistent Product Quality – The FX5U PLC’s PID control now maintains tighter temperature stability, improving overall bake accuracy and reducing waste.

Future-Ready Flexibility – The new safety controller architecture and modern PLC platform mean future production changes can be incorporated quickly without significant downtime.

Summary

The controls refurbishment has delivered:

• A modern, compliant and resilient control architecture

• Improved safety, diagnostics and operator visibility

• Quantified energy savings

• Enhanced production consistency

• Stronger long-term reliability and reduced maintenance effort

By combining Mitsubishi Electric automation with modern functional safety principles, we delivered a reliable, future-ready control platform that enhances performance and supports long-term operational needs.

“We chose Control Freaks because they understand our processes and always deliver work that we can trust. This project has reinforced why we continue to rely on them.”

– The Client, Engineering Manager.

If you would like to learn more about how we can support your next controls or automation project, please take a look at the services we provide or get in touch with a member of our team.